Polyurethane was first developed by Germany. Used as a foam and adhesive.

The paint industry developed polyurethane alkyd resins and the like in the 1960s to make paints. In the past more than a decade, the ink industry has also begun to conduct research, and polyurethane quick-drying ink has been put into the market. Because of its characteristics, it is possible to establish a foothold in the ink industry in the future.

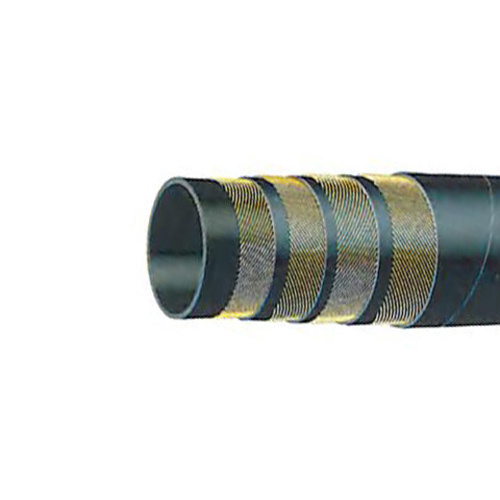

In the printing industry, the use of polyurethane rubber rollers has a long history.

Its most basic reaction is the reaction of isocyanate groups (R-N=C=O) with hydroxyl groups of polyesters, polyethers, ethylene glycol or castor oil. Followed by its reaction with water. Other hydrogen-containing compounds, such as carboxyl and amines in the oil, can also react with it.

In the production of such resins, the base material is diisocyanate toluene (T.D.I or toluene diisocyanate). It is made from 2,4 diaminotoluene and two molecules of phosgene (COCl2). Because it is a very toxic chemical, it mostly uses prepolymers of ethylene glycol or other polyols. Non-toxic) In this type of prepolymer, there are also unreacted isocyanate groups, which can also react with polyols and esters and the like.

In the coatings industry, polyurethane coatings are divided into two major categories, namely single-component and two-component.

The single component is divided into three types:

(1) Urethane oil (isocyanate modified dry oil).

(2) Isocyanate-terminated adducts or prepolymers (wet-cured).

(3) Blocked isocyanate (thermoset).

Divided into two categories:

(1) Isocyanate-terminated adducts or prepolymers, hydroxyl-containing compounds.

(2) Prepolymers similar to (2) in the above single component, and a contact agent (mostly amines and metal naphthalates).

This content has an enlightening effect for ink makers. Some have actually been accepted by ink manufacturers. The ink-related urethane oils are briefly described as follows:

Isocyanate modified dry oils, also known as Urethane Oil, or Uralkyd. It is derived from the reaction of diisocyanates with hydroxyl-containing drying oils. The ratio of NCO/OH is 1 or less. Its curing reaction includes the oxidative polymerization of double bonds of dry oil fatty acid molecules. Therefore, the curing mechanism is similar to the alkyd resin and is a cross-linking reaction.

In general, unsaturated glycerides (such as linseed oil) are first subjected to alcoholysis with a polyol. The ratio of unsaturated glycerides to polyols should control the average number of hydroxyl groups per molecule in the mixed hydroxy ester. The alcoholysis method is as follows: Fill the linseed oil into a container, add lead oxide as a catalyst, heat to 80° C. within 15-20 minutes, add the polyol, raise the temperature to 230-240° C., keep it for 25-30 minutes, and inspect it. The degree of alcoholysis is completely (the alcoholysis of dehydrated castor oil is based on the use of caustic soda as a catalyst). Carbohydrate oil is then produced with the alcoholized oil: 50 g of oil and 25 g of xylene are placed in a container and a mixture of diisocyanate toluene and xylene is slowly added dropwise over 25 minutes. The reaction temperature is about 90°C, and the reaction can take about one and a half hours. The amount of diisocyanate used is NCO/OH ratio of 1 or less, and there is no free diisocyanate in the product.

In this product, the diisocyanate and hydroxy ester are linked together, increasing the molecular weight and functionality (increasing the unsaturation).

This low molecular weight polyester-urethane binder contains four unsaturated fatty acid residues:

R=CH3CH2CH=CHCH2CH=CHCH2CH=CH(CH2)7

Therefore, desiccants can be oxidized and dried to form high molecular weight polymers. Its film-forming properties are excellent.

The hydroxyl value of the alcoholylated product is critical to the nature of the film. Similarly, in the case of linseed oil products with glycerol, if the content of diglyceride is too high, there is no benefit to the film.

It has been achieved to make linseed oil alkyd resin with diisocyanate or its prepolymer instead of one or all of the phthalic acid and used in ink.

After the resin is formed into a film, it has a firm resistance to abrasion, a good wettability of the pigment, and excellent printing performance in plain printing. The poorer ones have higher prices.

According to U.S. Patent 3,412,054, polyurethane resins can also be made water-reducible. That is, the polyisocyanate is reacted with 2,2bis(hydroxymethyl)carboxylic acid and then reacted with ammonia or an amine.